In the rapidly evolving world of electronics, flexible PCBs are becoming increasingly indispensable. As technology pushes the boundaries of design and functionality, flexible PCBs are at the forefront, providing innovative solutions that traditional rigid boards simply cannot match. Renowned expert in flexible electronics, Dr. Emily Chan, states, "The adaptability and efficiency of flexible PCBs are revolutionizing the way devices are designed and manufactured." This encapsulates the essence of why flexible PCBs are gaining traction across various industries.

From consumer electronics to medical devices, the benefits of using flexible PCBs extend far beyond mere convenience. They offer significant advantages in terms of space-saving, weight reduction, and enhanced reliability under various environmental conditions. As organizations strive to create more compact and efficient products, flexible PCBs stand out as a crucial component, enabling new possibilities in design and functionality. This article delves into the top 10 benefits of using flexible PCBs in modern electronics, showcasing how they contribute not only to performance enhancements but also to innovative breakthroughs across diverse applications.

From consumer electronics to medical devices, the benefits of using flexible PCBs extend far beyond mere convenience. They offer significant advantages in terms of space-saving, weight reduction, and enhanced reliability under various environmental conditions. As organizations strive to create more compact and efficient products, flexible PCBs stand out as a crucial component, enabling new possibilities in design and functionality. This article delves into the top 10 benefits of using flexible PCBs in modern electronics, showcasing how they contribute not only to performance enhancements but also to innovative breakthroughs across diverse applications.

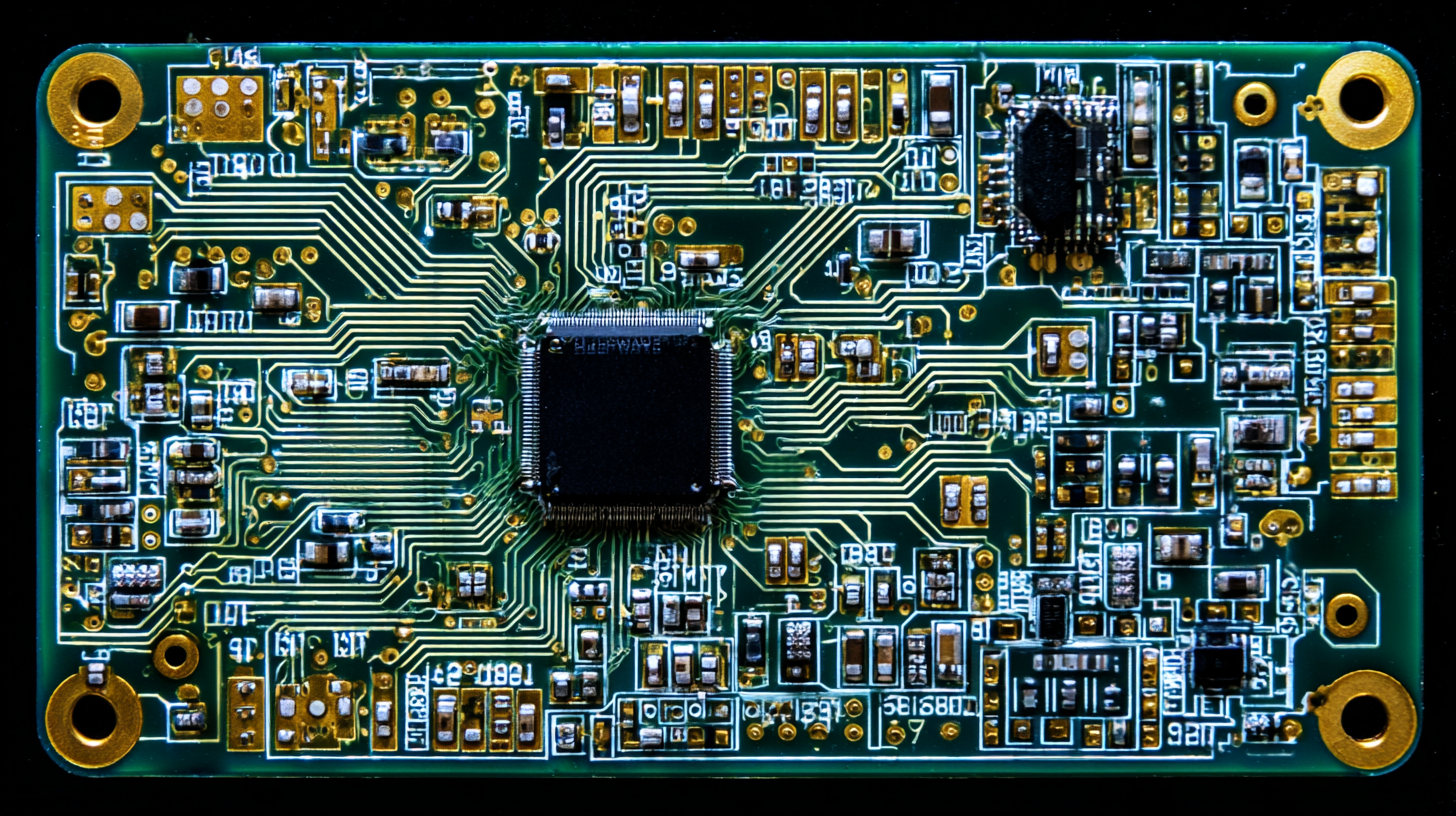

Flexible PCBs (printed circuit boards) offer significant advantages in modern electronics, particularly when it comes to space-saving designs. Their ability to bend, twist, and fit into compact spaces allows for the development of devices that can be both lightweight and efficient. This flexibility not only enhances the design potential but also enables manufacturers to create more intricate and complex layouts, ultimately leading to more functional and powerful electronic products.

Flexible PCBs (printed circuit boards) offer significant advantages in modern electronics, particularly when it comes to space-saving designs. Their ability to bend, twist, and fit into compact spaces allows for the development of devices that can be both lightweight and efficient. This flexibility not only enhances the design potential but also enables manufacturers to create more intricate and complex layouts, ultimately leading to more functional and powerful electronic products.

Moreover, the use of flexible PCBs can significantly reduce the overall size of electronic devices. By eliminating the need for bulky connectors and traditional rigid board layouts, designers can optimize the internal architecture of products such as smartphones, wearables, and medical devices. This results in slimmer profiles and decreased weight, making electronics more portable. Additionally, the integration of flexible PCBs can lead to better thermal performance, as they can be designed to dissipate heat more effectively. The combination of these factors illustrates how flexible PCBs are not only practical but also transformative, pushing the boundaries of modern electronic design.

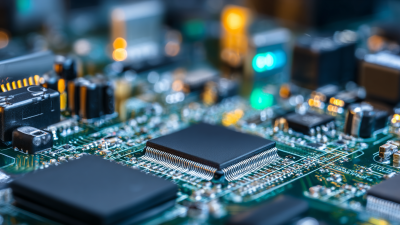

Flexible PCBs (Printed Circuit Boards) offer enhanced durability and reliability, making them an ideal choice for modern electronics that operate under varying environmental conditions. Unlike traditional rigid PCBs, flexible circuits are designed to bend, twist, and conform to different shapes while maintaining their functionality. This adaptability not only helps in saving space but also significantly reduces the risk of breakage and failure due to external stresses. The ability to withstand mechanical flexing is particularly beneficial in applications where components are subjected to frequent movement or vibration, such as in wearable devices and mobile electronics.

Moreover, flexible PCBs are generally more resistant to thermal and chemical stresses, allowing them to perform reliably in harsher conditions. They can endure a wide range of temperatures and are less prone to moisture absorption, which further enhances their longevity. As electronics continue to miniaturize and become more complex, the ability of flexible PCBs to maintain integrity under various conditions ensures that devices remain functional and durable over time. This reliability is crucial for industries such as automotive and aerospace, where performance and safety are paramount.

Flexible PCBs (Printed Circuit Boards) are rapidly becoming a staple in modern electronics due to their

cost-effectiveness in manufacturing. One of the primary advantages of flexible PCB technology is the reduction in production costs that manufacturers can achieve.

Traditional rigid PCBs often involve multiple complex processes to create the necessary layers and connections, while flexible PCBs streamline this by integrating multiple functionalities into a single layer.

This simplification not only cuts down material costs but also reduces labor expenses associated with assembly and testing.

Moreover, the versatility of flexible PCBs allows for improved design flexibility, which can lead to cost savings in the product development phase.

Engineers can design compact and innovative electronic devices without the constraints of rigid boards, enabling more efficient use of space and resources.

This adaptability can also shorten the time to market, further enhancing cost-effectiveness.

Additionally, with advancements in flexible PCB materials and fabrication techniques, manufacturers are finding that the long-term reliability and durability of these boards contribute to lower overall lifecycle costs in electronic devices.

In the rapidly evolving landscape of modern electronics, thermal management remains a critical challenge, particularly for high-performance devices. The integration of flexible printed circuit boards (PCBs) offers a groundbreaking solution, enabling enhanced heat dissipation which is essential for maintaining optimal performance. According to a report by IDTechEx, the flexible PCB market is expected to grow significantly, with thermal performance being a key driver. These flexible boards, made with advanced materials, facilitate better heat spreading and enable designers to create more compact and efficient devices.

Flexible PCBs are uniquely suited for applications going beyond traditional rigid boards due to their ability to conform to different shapes and sizes. This adaptability not only optimizes space but also aids in creating pathways for heat to escape more efficiently. A study from IPC found that devices utilizing flexible PCBs exhibit up to a 25% improvement in thermal performance compared to their rigid counterparts. This enhanced thermal management is crucial for high-performance electronics like smartphones, wearables, and automotive systems, where temperature control directly impacts performance and reliability. As manufacturers continue to demand higher functionality in smaller packages, flexible PCBs are poised to play a pivotal role in meeting these complex requirements.

Flexible PCBs (Printed Circuit Boards) are revolutionizing the way electronics are designed and manufactured, particularly in terms of simplifying assembly and integration processes. Unlike their rigid counterparts, flexible PCBs can be bent and shaped to fit into compact spaces, resulting in a significant reduction in the number of components required. A study by the Institute of Electrical and Electronics Engineers (IEEE) indicates that using flexible PCBs can cut assembly time by up to 40%, allowing manufacturers to accelerate product development cycles without sacrificing quality.

The lightweight and thin profile of flexible PCBs also contribute to easier integration within devices. They eliminate the need for bulky connectors and complex interconnections, as they can be directly adhered to surfaces, creating a seamless integration within multi-layer assemblies. According to a market report by Technavio, the demand for flexible PCBs is projected to grow at a CAGR of 10% through 2025, reflecting the industry's shift toward more compact and efficient electronic designs. As companies seek to create more advanced gadgets that prioritize space and performance, flexible PCBs stand out as a key component in modern electronics engineering.

| Benefit | Description | Application |

|---|---|---|

| Space Efficiency | Flexible PCBs can be bent and twisted to fit into compact spaces. | Wearable devices |

| Weight Reduction | They are lighter than traditional rigid boards, enhancing portability. | Smartphones |

| Design Flexibility | Allows for innovative designs and complex geometries. | Medical devices |

| Reduced Assembly Time | Simplifies the assembly by integrating multiple layers into one. | Consumer electronics |

| Improved Durability | More resistant to shock and vibration than rigid boards. | Automotive applications |

| Cost-Effectiveness | Lower manufacturing costs for small to medium production runs. | Prototype development |

| Enhanced Signal Integrity | Reduced electromagnetic interference (EMI) due to short and direct paths. | RF applications |

| Thermal Management | Better heat distribution due to flexible materials. | High-performance computing |

| Ease of Integration | Can be easily integrated with other components. | IoT devices |

| Aesthetics | Sleek designs that enhance product appearance. | Consumer gadgets |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |